Building with Spinifex investigates the fabrication based applications of the spinifex grass, convening anthropologists, architects, bioengineers and members of the Indjalandji-Dhidhanu community to harness the traditional harvesting practices and the science of spinifex.

The project is carried out on the traditional lands of the Indjalandji-Dhidhanu people, 190 km drive north-west of Mount Isa in Queensland, and is overseen by the Myuma group; a group of non-profit corporations owned by the Indjalandji-Dhidhanu people. Here with a team of over 80 staff members, spinifex is grown by the ton, a hardy perennial tussock grass found across more than two-thirds of Australia’s vast inland desert. The project's operations hub synergises both emergent technologies and ancient cropping techniques, utilising a mass spectrometer, supercritical CO2 extraction plant, state-of-the-art ceramic ball mill and high-pressure homogeniser, harnessing the benefits of both contemporary and ancient cultural and scientific practices.

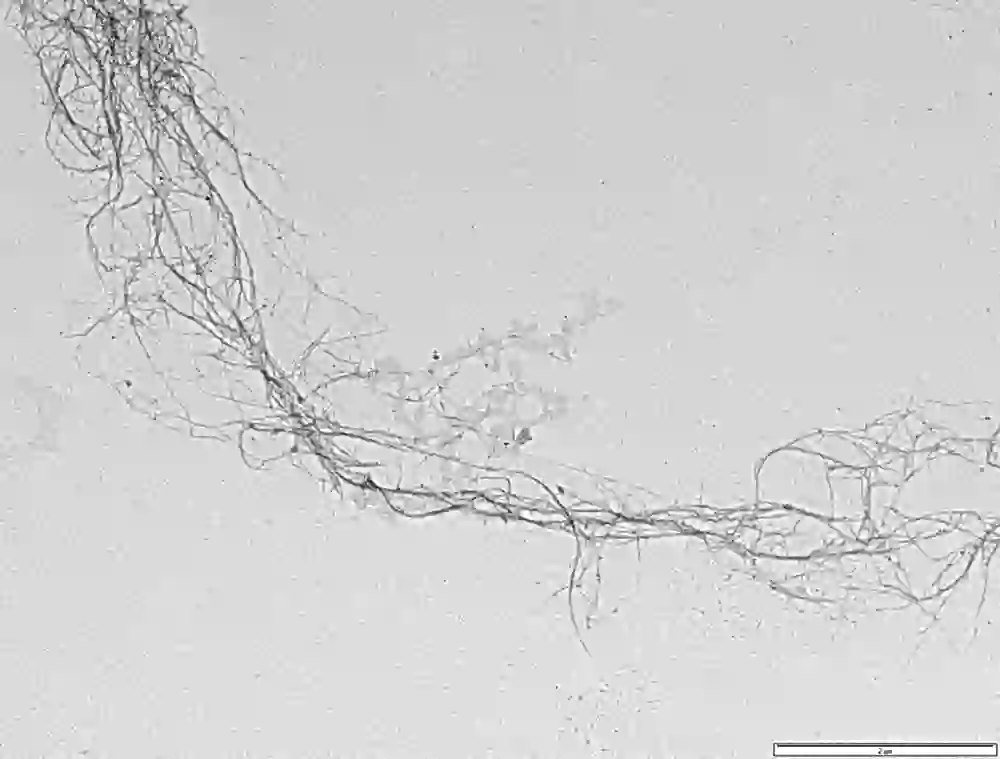

The project's key aim is to reimagine the role of spinifex and First Nations expertise in the contemporary landscape of material fabrication. The project demonstrates how together spinifex and First Nations culture can transform the production of materials such as latex, rubber, plastics and carbon fibres according to the project's leaders. Team member Dr Harshi Gamage highlights that ‘if we can use these products in our buildings and in our housing, we can make insulated batts using the fibre, which will reduce the use of air-conditioning’. The project has already evidenced the material benefits and unique properties of spinifex, experimenting with the resin produced by the grass which when formed can act as glue or polymer with a tensile strength eight times greater than steel.

This piece has been written based on internet research and on previous interviews carried out with the team of University of Queensland and the Indjalandji-Dhidhanu community by outlets such as the ABC, Nature and Cosmos.